An innovative mindset enables us to continually improving our

scrubber system to maintaining superior performance and reliability

Starting as a developing company, continuous improvement and innovation are the DNA of PureteQ – it is who we are. This mindset has led to several improvements of our scrubber system, as we always seek new, better and more cost-efficient ways of doing things.

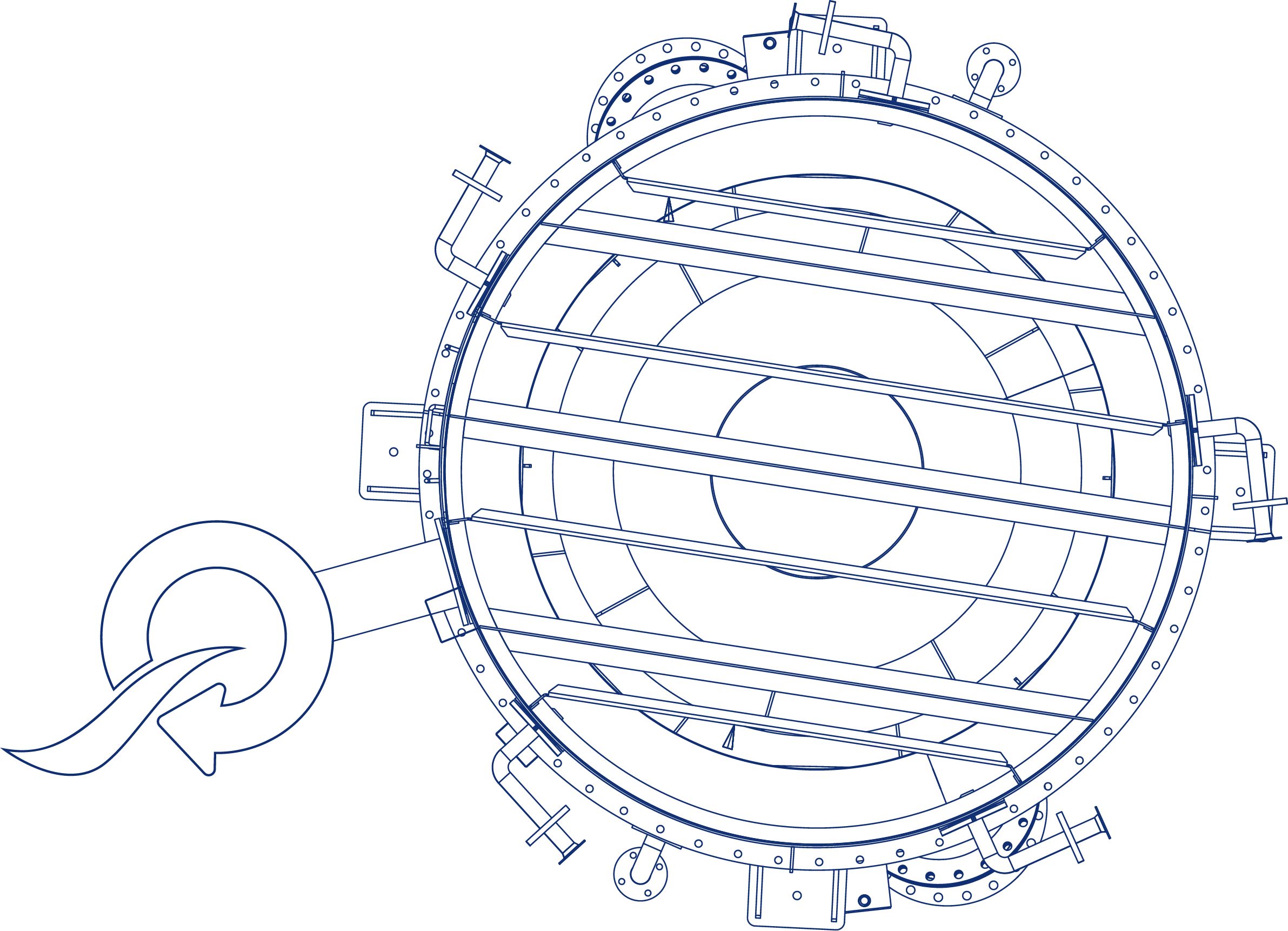

With its hydrodynamic fluid distribution system, the PureteQ Maritime Scrubber outperforms most traditional scrubber systems in terms of safety features, weight and energy efficiency.

Innovation is not limited to our maritime scrubber system but also relates to our project execution. PureteQ has created efficient tools to enhance rewarding collaboration between all stakeholders in scrubber projects.

One of these tools is a state-of-the-art project management system enabling PureteQ to monitor progress and the current state of all documents to keep the project on track to minimize the off-hire period.

To help combat climate change we are committed to continuously optimize our systems and invest in research and development of new technologies within the fields of Carbon Capture and Power-to-X.

PureteQ Maritime Scrubbers therefore now come as onboard carbon-capture-ready. Scrubber systems with room for a solvent-based Onboard Carbon Capture (OCC) integration resulting in a CO2 reduction of 30-60% of a ship’s exhaust gas, depending on ship type.

In collaboration with our sister company ESTECH A/S we have developed a combined carbon capture and power-to-x technology that is unique in its approach to carbon capture merging two operations in one circular process that converts toxic flue gas or exhaust gas into storable and transportable forms of energy or fuels. By relying on PureteQ’s patented exhaust gas purification technology, based on hydrodynamic fluid distribution, ESTECH was able to accelerate the product development process.