We supply built-to-fit scrubber systems to shipowners who want to save money on fuel by continuing use of heavy fuel oil (HFO). Our offices in Europe and Asia provide prompt worldwide coverage and after-sales service.

According to the research organization SINTEF, scrubbers are the most climate-friendly mean of 2020 compliance and, as an additional benefit, they save more lives by reducing particle pollution.

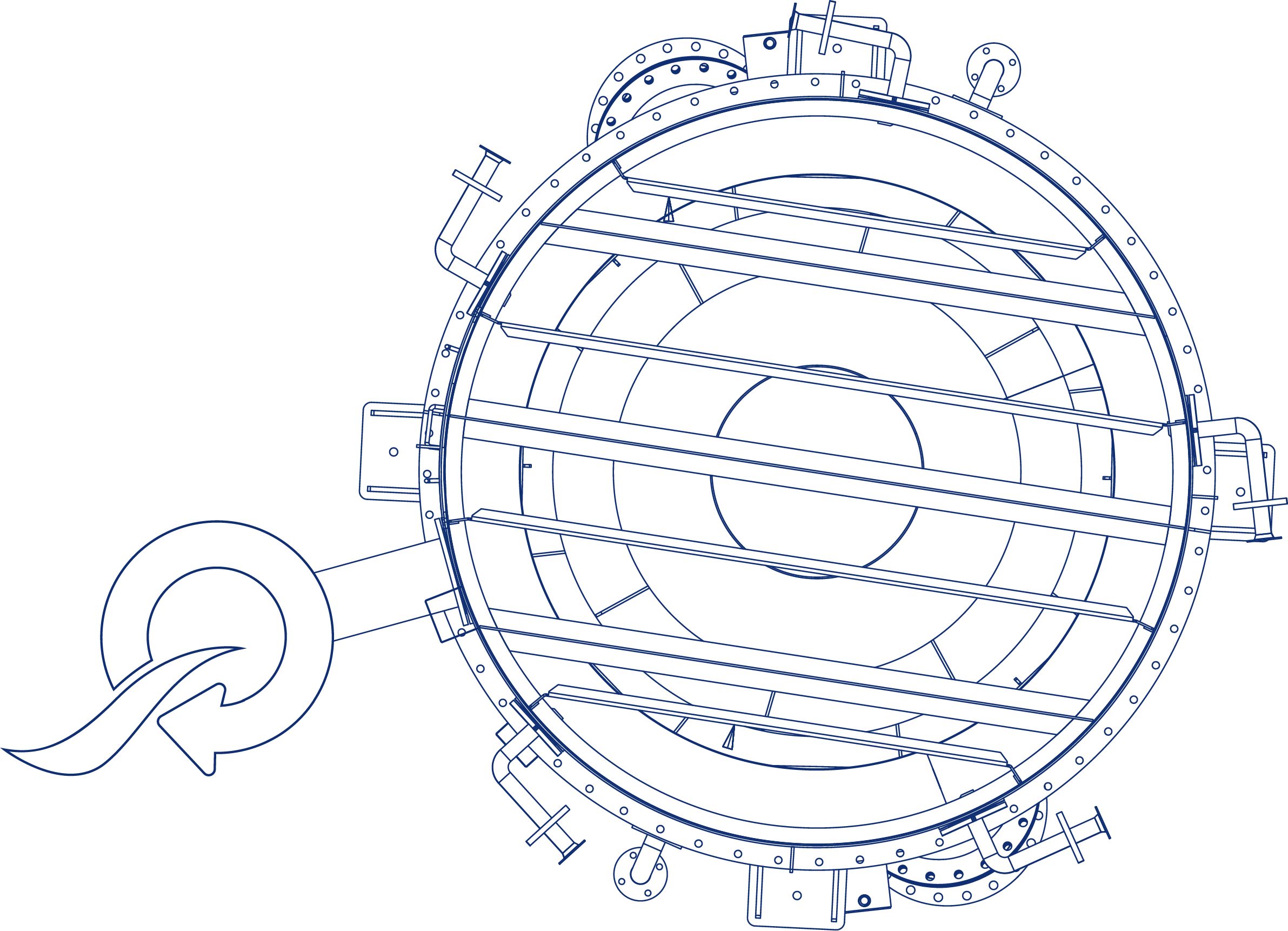

Read brochure Play videoThe PureteQ Maritime Scrubber System is the most energy-efficient, reliable and safe scrubber system on the market. It is available as open loop, hybrid ready and fully hybrid (closed loop, with and without bleed-off). All our scrubbers come with a user-friendly control system with real-time remote access.

To help combat climate change we are committed to continuously optimize our systems and invest in research and development of new technologies within the fields of Carbon Capture and Power-to-X. PureteQ Maritime Scrubbers therefore now come as onboard carbon-capture-ready. Scrubber systems with room for a solvent-based Onboard Carbon Capture (OCC) integration resulting in reduction of a ship’s CO2 emission.

The PureteQ Maritime Scrubber System has low power consumption due to a patented hydrodynamic fluid distribution and an open tower construction, which enables low back pressure. It comes with a state-of-the- art control system with complete remote accessibility and an energy optimisation programme. It features the best, most reliable components from renowned suppliers and it is reasonably priced. All of this ensures low operational expenditures (OPEX), a short Return On Investment (ROI) and superior lifelong performance.

PureServ is PureteQ’s dedicated service organization that provides service and support to all brands of scrubbers and sensors.

We encourage all shipowners to realise the full potential of scrubber systems by entering into a PureteQ Service Agreement to safeguard continuous operation, reliability and MARPOL compliance. Our marine engineers are available 24/7 and dispatched from Europe or Asia. This entails expert support and guidance for all scrubber systems on-site or via the safe PureteQ remote system, depending on the ship’s conditions and the client’s requirements.

PureteQ has developed a Windows-based Human Machine Interface (HMI) control system that can be operated manually or automatically according to customer preferences and crew skills. Remote accessibility permits PureteQ staff to perform system upgrades and assist the crew with online troubleshooting. The open data protocols provide shipowners with easy integration of compliance and performance data into other systems, as well as easy reporting, which saves manhours.

Some shipowners prefer PureteQ Marine Engineers to monitor the scrubber system and provide compliance and performance reporting, as well as online guidance to the crew.

Most of the scrubber systems we sell are open-loop hybrid-ready solutions, but quite a few are complete hybrid-loop systems. Hybrid-ready means that the system is prepared for hybrid operation to give shipowners and operators the opportunity to go through with a less costly upgrade to a complete hybrid system, if required later on.

The difference between a hybrid/closed loop configuration and an open loop is the addition of a water-treatment facility and related equipment that enables the recirculation of wash water in the scrubber system and the discharge of a small amount of treated water. The water-treatment system is designed to conform to the ship’s specific operational pattern. PureteQ only delivers first-rate and thoroughly tested brands.

The key to a successful project is close communication with all stakeholders. PureteQ guides the shipowner throughout the process from initial design to final approval of the system and installation by the Flag State. With our state-of-the-art project management system we monitor progress and the actual state of all documents to keep the project on track. In order to minimize the off-hire period, the designated project manager and his/her team guide every installation to optimize quality and efficiency during the installation process and handles commissioning as well as sea trials. The devil is in the detail – everything is double-checked to ensure that the system remains operational for many years.